NEAR-NET SHAPE

FORGINGS

At capacity? Have you considered a

partner to start with a near-net forging?

Forged parts may save you more than just time.

WHY FORGE FIRST?

CUSTOMERS AVERAGE

SAVED ON

MATERIAL COST

=

MORE SAVINGS

SAVED ON

CYCLE TIME

=

FASTER OUTPUT

SAVED ON

MACHINE COST

=

INCREASED CAPACITY

BENEFITS OF STARTING

WITH A NEAR-NET SHAPE

Starting with consistent near-net-shape forgings enhances part-to-part locations for fast output and less scrap. When Anchor Harvey forges first, you can eliminate your roughing program, saving 40% of the time to machine the completed part.

Cycle Time 22 Min.

Material Cost $10.00

Machine Cost $33.00

Total Cost

$43.00

VS

Cycle Time 6 Min.

Material Cost $20.00

Machine Cost $9.00

Total Cost

$29.00

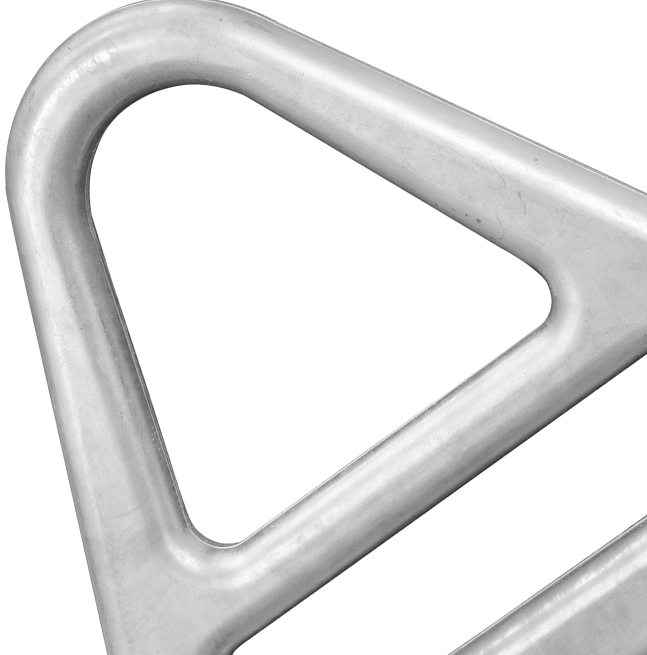

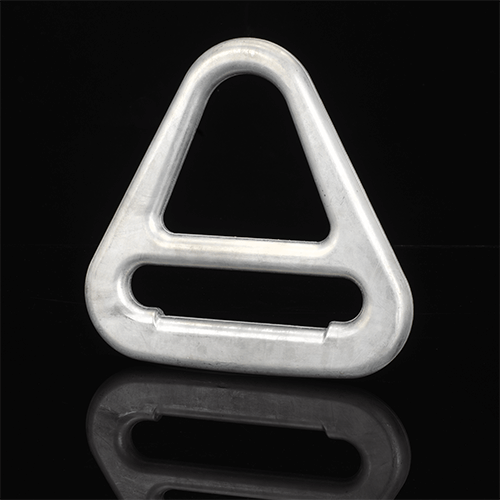

YOUR PARTS, OUR PROCESS

We forge precision aluminum components with lengths and widths up to 36" and weights from ounces to 50 lbs, based upon geometry. Aluminum forgings are stronger than cast aluminum, lighter than steel, and perfect for Machine Shop components.

DISCUSS YOUR JOB

WHY PARTNER

WITH ANCHOR HARVEY?

Strength in Your Partnerships, Strengthens Your Parts

IN-HOUSE

ENGINEERS

With an in-house team of engineers, we will convert your part from a billet to a near-net-shape design. We use forge design simulation software to ensure the most efficient use of material and the most efficient forging process.

CONSISTENCY BY

PROCESS CONTROL

Our investment in process control ensures consistent products from 1 to +1,000,000. You won’t find this degree of sophistication at another forge shop.

UNMATCHED

EFFICIENCY

Anchor Harvey’s cellular manufacturing process ensures one continuous workflow, and we have virtually eliminated WIP (work in process). We ship parts every day of the week, practice Six Sigma Methodology, and continue to introduce automation and robotics to our shop floor.

100-YEAR

LEGACY

Since 1923, Anchor Harvey has been manufacturing right here in the U.S.A. We have withstood the test of time and overcome every unforeseen economic challenge. Few companies are in the century club, and far fewer of those members are in forging.

AEROSPACE

MACHINE SHOPS

FORGE FOR LIFTOFF

AS9100 CERTIFIED PARTNER

We are AS9100 certified and continually investing in our growth in the aerospace market. For 25 years, we have forged parts for aerospace OEMs, Tier-1, and Tier-2 manufacturers serving commercial, military, and electric aircraft. Forged aluminum is relied upon as a superior, high-strength, and lightweight material for many aerospace applications. Anchor Harvey has the experience, commitment, and credibility you would desire from a trusted aerospace manufacturer. Contact us to get started.

SAMPLE AEROSPACE PARTS

ANCHOR HARVEY HAS FORGED:

Fastener Rails

Special Forging

Turbine Rings

Bearing Rings

Rotor Blade Components

Fuselage Structural Parts

Runway Light Covers

Valve Body

Seat Supports

Brake Calipers

Actuators

AUTOMOTIVE

MACHINE SHOPS

FORGE FOR DRIVE

TRANSFORMING TRANSPORTATION

Sedans or SUVs, motorsports or electric vehicles, if it belongs between two wheels or four and can be forged, we’ve forged it. If you’re looking for a manufacturing partner who has seen it and done it before, call Anchor Harvey. Anchor Harvey has evolved alongside the auto industry. We have the capability and capacity to handle higher volume production or highly engineered prototypes. Contact us to get started.

SAMPLE AUTOMOTIVE PARTS

ANCHOR HARVEY HAS FORGED:

Linkages

Struts

Axle Components

Suspension Parts

Drive Shaft Knuckles

Shocks

Hubs

DEFENSE

MACHINE SHOPS

FORGE FOR SAFETY

TRUSTED LEGACY

Anchor Harvey is a respected name in the defense space, with a reputation for excellence, especially within armaments. Anchor Harvey’s defense portfolio includes OEMs, private manufacturers, and government contracts. You can trust Anchor Harvey to treat your job with confidentiality. We are familiar with the detail and expectations surrounding defense jobs. Contact us to get started.

SAMPLE DEFENSE PARTS

ANCHOR HARVEY HAS FORGED:

Gyroscopes

Wheel Hubs

Tank Top Latch

Guidance Systems

Upper and Lower Receiver

Actuators

Receivers

Nose Cones