Why Anchor Harvey?

From managing the entire manufacturing process to procuring the highest quality materials from our trusted network of North American and global suppliers, Anchor Harvey’s agile and innovative team gets high quality components developed and to market more quickly and efficiently for our customers.

Customers that work with Anchor Harvey can be confident that our comprehensive supply chain process meets our exacting specifications and quality standards.

Why Anchor Harvey?

From managing the entire manufacturing process to procuring the highest quality materials from our trusted network of North American and global suppliers, Anchor Harvey’s agile and innovative team gets high quality components developed and to market more quickly and efficiently for our customers.

Customers that work with Anchor Harvey can be confident that our comprehensive supply chain process meets our exacting specifications and quality standards.

North American & Global Sourcing Solutions

Supply chain challenges? We solve them before they happen. With over 100 years of experience in manufacturing and supply chain management, we understand the urgency of keeping production running smoothly. Whether you’re managing fluctuating demand, sourcing complex materials, or navigating logistics constraints, our expert team brings real-world solutions backed by deep industry knowledge.

- Strategic Sourcing: We source raw materials from trusted suppliers in the United States, Mexico and China, ensuring flexibility, quality, and reliability.

- Vendor Relationships That Work for You: Our long-term supplier partnerships allow us to secure competitive pricing and shorter lead times.

- Scalable Support: From prototyping to volume production, our supply chain adapts to your project’s needs.

Material Procurement

Working hand-in-hand with our network of suppliers and partners, we’ve cultivated a quick and organized supply chain process that encourages fast turnarounds and consistent product quality for our customers’ needs.

For customers with forging projects, materials we commonly source from North American suppliers include are:

- 2000 Series Aluminum: Valued for its incredibly high strength and rigidity, these alloys are used for the production of high-strength and high-performance parts in aerospace and other high-stress applications.

- 6000 Series Aluminum: A versatile and weldable material, these alloys are used for general purpose applications in aerospace, automotive, maritime, and more.

- 7000 Series Aluminum: A high-strength and versatile option, these alloys are used for structural needs like airframe plating and wing structures.

For customers needing low-cost solutions in their machining projects, materials we commonly source from global suppliers:

For customers needing low-cost solutions in their machining projects, materials we commonly source from domestic and global suppliers include ductile iron and steel.

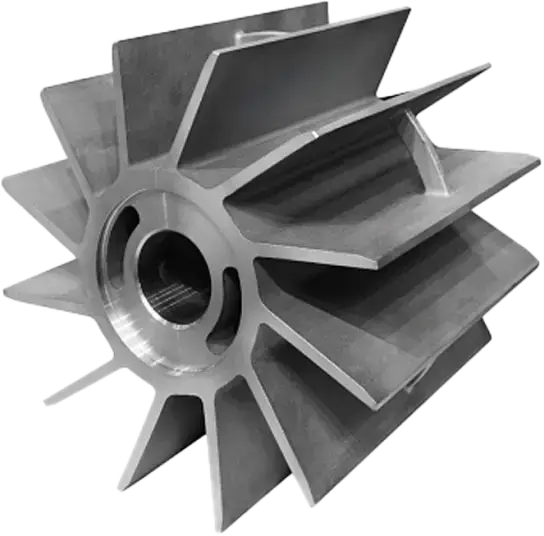

Post-Forge Machining

For plates or parts that need post-forge machining to form a water- or airtight seal under high pressure, our machine shops can perform milling, turning, grinding, electric discharge cutting, burnishing, and drilling to tolerances within microns.

Assembly & Inspection

We provide a suite of onsite assembly services to allow our customers to receive fully assembled parts ready for immediate use. For those requiring assemblies or sub-assemblies to be completed before arriving at their facility, we leverage a robust network of trusted assembly shops to handle nearly any type of component or system.

Our onsite inspection capabilities and dedicated quality control personnel perform thorough in-house inspections to ensure every finished part meets strict quality standards. We also offer full-service forging inspection and material testing across a range of industries—and partner with trusted labs for fast turnaround on specialized analyses when needed.

Anodizing

Anchor Harvey provides anodizing services for customers that need an incredibly tough, scratch-resistant, corrosion-resistant, chemically stable protective layer for their products.

Plating and Coating

For customers looking for a specific aesthetic (commonly in the specialty automotive and aerospace industries), Anchor Harvey provides quality plating and coating services that bonds a thin layer of metals or minerals to the surface of a part.

Heat Treating Process

Consistently recognized by major OEMs as “the best of all worlds,” our CQI-9 compliant in-house heat treating process is built into the full production process. This ensures every forged part gets the right treatment for its application.

Because heat treating is done onsite, lead times are shorter and our team can monitor and adjust the process in real time. The CQI-9 compliant system delivers results that exceed ASTM standards, with up to a 15% improvement in part performance.

Shipping

Our comprehensive production lifecycle is truly end-to-end, with the ability to ship our customer’s products upon project completion. Since we oversee the entire supply chain from start to market, we give customers the confidence that their projects are completely covered throughout the entire process.

INSIGHTS & EDUCATION

Featured Capabilities

Featured Capabilities

CAREERS