Paid for a couple's morning coffee and donuts at Donut Delight

To our valued customers, employees, and partners; This year Anchor Harvey achieves a business milestone by turning 100 years old. Anchor Harvey opened its doors for business in March of 1923. During the century that followed, Anchor Harvey continually innovated and discovered ways to meet the demands of our customers in an ever-changing marketplace.

We would like to take this moment to say “thank you” to all the great customers we were able to serve over the years. Working with you has been our pleasure. To all the many employees who poured their hearts and souls out during the humble beginnings, to all the current day world-class professionals working in a high-tech manufacturing company, to our valued business partners who worked arm to arm with us through all the years, our sincere, heartfelt, thank you.

To the next historic 100 years of forging for the best, by the best, and with the help of the best partners.

Countless people have helped carry out the Anchor Harvey mission for 100 years. Our employees, customers and partners have collaborated to build better products, from lifestyle brands to life-saving devices. Thank you for partnering with Anchor Harvey and sharing the highlights of your experiences!

Anchor Harvey emerged from the grit of the American Industrial Revolution. Since then, we have evolved from a brass and bronze forging shop to a data-driven aluminum forging company.

On June 20, Harold Brown Harvey, the future founder of Harvey Metal Corporation, is born in Parkman, Maine. By age 35, he would distinguish himself in the electrical engineering sector by founding the Marquette Electric Engineering and Switchboard company in 1915 and the Harvey Electric Company in 1919.

Harold B. Harvey founds Harvey Metal Corporation in Chicago, Ill., amid rapid growth in the electrical industry. Harvey Metals forged copper and copper alloys as well as an exotic metal—aluminum.

Harvey Metal Corporation becomes the first company to use the Ford Air Express, the world's first regularly scheduled commercial cargo airline, created by Ford Motor Company. It flew forged aluminum components from Chicago to the Ford airplane production plant in Dearborn, Mich.

Under the direction of the United States War Production Board, Harvey Metal Corporation turns to wartime production. It mass-produced brass munition components and aluminum airplane parts.

After World War II, the Harvey Metal Corporation is purchased by Chicago Extruded Metal, a brass mill in Cicero, Ill. Extruded Metal had been the brass material supplier to Harvey Metals since 1923.

Harvey Metal Corporation becomes the first forging plant to produce drop-forged brass, thanks to an invention by founder Harold B. Harvey. The new production method gave brass components added strength for heavy-duty applications like automotive frames. Over the next three decades, Harvey Metal continues to be a leading brass and aluminum forging shop in Chicago.

Harvey Metal Corporation merges with another division of Chicago Extruded Metal, Anchor Screw Products, to form Anchor Harvey Components in Addison, Ill. Anchor Harvey is a full-service production plant that can forge, machine, and heat treat products entirely in-house.

Anchor Harvey builds a modern 100,000-square-foot forging and machining facility in Freeport, Ill., and begins relocating.

Anchor Harvey finishes moving to its new 100,000-square-foot facility in Freeport, Ill. The following decade brings tremendous expansion. From the early to late 1980s, Anchor Harvey grows from one full shift to three, despite the global recession.

A private investment group purchases Anchor Harvey. Larry Fey transitions from sales manager to president of the company.

The passage of the North American Free Trade Agreement (NAFTA) increases foreign competition for brass forging. For long-term viability, Anchor Harvey shifts from primarily brass to aluminum forging. The transition would take several years.

Anchor Harvey acquires its first computer numerical control (CNC) machine, a Milltronics lightweight vertical CNC mill. At the time, only one employee at the company was able to create the G-code programs for the machine.

Anchor Harvey is purchased by Boler Ventures LLC. Other Boler companies include Hendrickson, a global leader in heavy-duty suspensions, and Watson and Chalin, a manufacturer of truck and trailer axles and suspensions.

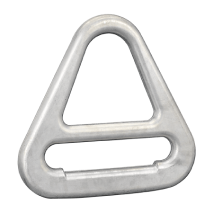

Anchor Harvey adds archery to its industries served. As part of the transition to aluminum forging, Anchor Harvey partners with Matthews Archery to produce aluminum frames for competition bows.

Anchor Harvey invests in improvements and growth to achieve the ISO 9001:2000 Certification. The credential demonstrates Anchor Harvey’s dedication to producing the most reliable, consistent, and top-quality forgings available.

Anchor Harvey settles a labor union dispute and overhauls much of its workforce.

A student intern from The Ohio State University writes a report on the inefficiencies of Anchor Harvey’s batch production method, prompting the examination of new production methods.

Anchor Harvey installs the first Weingarten screw press (5,000 ton), increasing capacity and adding new production capabilities.

Facility renovations begin to support a cellular manufacturing process. The new process replaces Anchor Harvey’s five-step batch production with one continuous workflow.

Anchor Harvey installs a full single-piece flow production line. The method proves to be vastly more efficient than batch production, leading to the installation of multiple lines over the next few years.

Continued growth requires a significant building addition, expanding the Anchor Harvey facility to 110,000 square feet.

The second Weingarten screw press (5,500 ton) is added to production.

Anchor Harvey invests in process control monitoring technology to regulate the manufacturing process from start to finish.

Improved production capacity wins Anchor Harvey its biggest customer contract to date, manufacturing motorcycle components for Harley-Davidson.

The third Weingarten screw press (4,700 ton) is installed, and the fourth (2,400 ton) becomes operational.

Five cellular workflows are completed, offering customers unmatched lead time and speed-to-market. Now, a single component can be manufactured in less than 48 hours, and each line can produce thousands of parts per day.

Anchor Harvey hosts its first company picnic. These picnics would become a staple of the company culture and rival small carnivals in size.

Anchor Harvey launches an update to its company branding.

Anchor Harvey continues improving its production lines. It adds extended loading belts that reduce time spent loading parts and begins fitting automation.

Anchor Harvey achieves AS-9100 certification, a set of quality management standards for the defense and aviation industries.

Anchor Harvey invests in specialty processes to achieve NADCAP Certification (National Aerospace and Defense Contractors Accreditation Program).

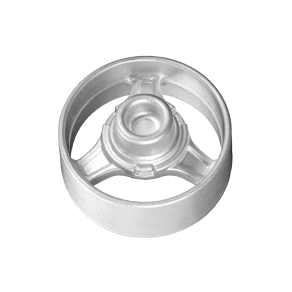

With the onset of the COVID-19 pandemic, Anchor Harvey rapidly shifts production to respirator valves for Tycho-Scott. Anchor Harvey produced the valves in low numbers before the pandemic, but the sudden need for respirators increased the demand by 2,600%.

Anchor Harvey launches its Electric Vehicle (EV) Workgroup to address the growing need for lightweight aluminum vehicle components critical to EV production.

Anchor Harvey looks ahead to a bright future amid growing demand for electric vehicles, the increased automation of production lines, and continued company growth.

Anchor Harvey plans to implement robotics in forge operations and packaging, which will revolutionize the operation of the factory floor. Within 10 years, it hopes to fully automate production lines with robots.

As makers and consumers of our customers’ products, we understand how each forging impacts the final experience. That is why we have pushed the boundaries of innovation since 1923.

As the needs of our customers and the world evolve, so do we. We will always aim to improve upon The Anchor Harvey Way, even after a century in business. Partner with Anchor Harvey now, and you will never look back.

You will only find our degree of sophistication at Anchor Harvey. We technically monitor our process, product, and customer satisfaction to ensure consistent products from 10 to +1,000,000.

READ MORE

Throughout our 100 years of experience, we’ve gained the expertise to systematize our facility. The result? Our customers can achieve an unmatched lead time and speed-to-market.

READ MORE

We build long-term, trusting relationships with our customers. Our proven expertise, commitment to transparency, and highly engaged workforce create a truly personal experience.

READ MORE