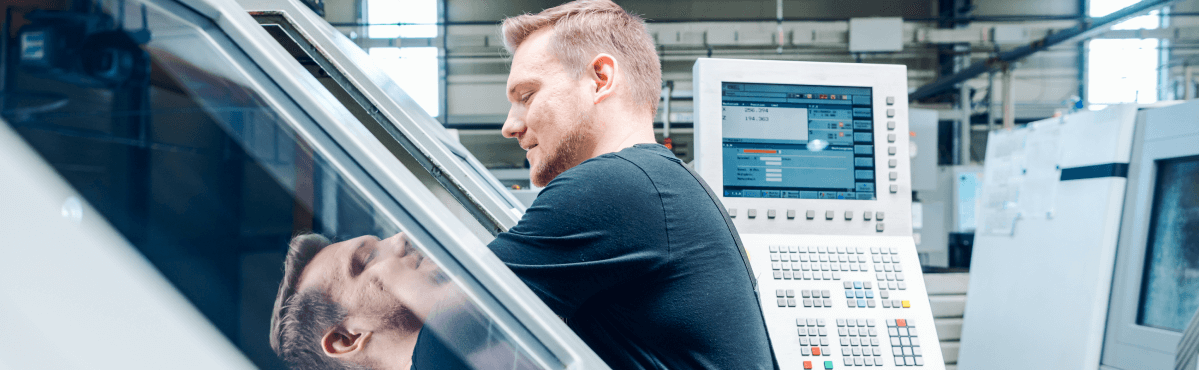

CNC MACHINING EQUIPMENT & CAPABILITIES OVERVIEW

At Anchor Harvey, our continuous investment in the latest CNC machining technology and equipment ensures a quality product – each and every time.

With multiple domestic and international fully equipped CNC machining facilities in our arsenal, our customers can trust that our highly-skilled, innovative team is ready to deliver the highest quality machined parts to propel their business forward.

Our extensive CNC machining equipment catalog includes more than 130 CNC machines, including:

- Multiple CMM’s with Zeiss as a standard

- 3, 4, and 5 Axis Mills

- 3, 4, and 5 Axis Vertical Machining Centers

- 4 Axis Horizontal Machining Centers

- 5 Axis Multi-Spindle Mill Turns

- Single and Dual Spindle Live Tool Lathes

- Swiss Lathes

- Vertical Turning Centers

- Zoller Inspection and Measurement Machines – which are standard across our facilities

- 3D Scanner

- Part Washing Equipment, including Jenfab 360-1 – 360° rotary ultrasonic washer, 2 stage separate wash and rinse tanks, and 5 micron filtration

Our continuous investment in the latest technology and equipment ensures a quality product – each and every time. Discover how Anchor Harvey’s CNC machining services can be the ultimate solution for your manufacturing needs.

Engineering Services

Combining Anchor Harvey’s in-house engineers’ extensive manufacturing knowledge with the latest technology and equipment, we work with our customers to redefine expectations and achieve solutions to CNC machined projects of any size and complexity. Our collaborative, data- and quality-driven process ensures that our customers’ vision is always achieved.

Engineering services we offer include:

- Advanced mechanical 3D solid modeling

- Reverse engineering

- Design options and considerations for manufacturing and improvement

- CNC programming

- CNC simulation for verification

- Overengineered cost avoidance

- Process and design improvement

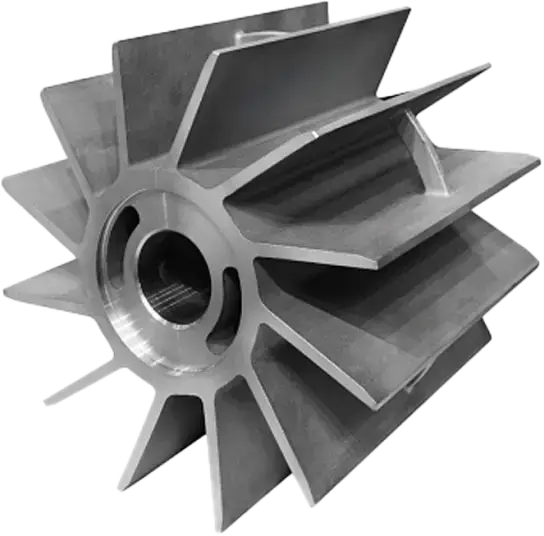

Precision Machining

With our extensive inventory of CNC machine equipment in multiple locations, our customers can be assured that our well-equipped team can handle any metal component need.

Our precision machining capabilities include:

- Batch to high-volume production

- Multi-axis milling and turning

- Multi-spindle turning

- Machining of exotic metals, including aluminum, iron, and more

- Size ranging from “.040” to “78” in diameter

- CNC machining down to .0001” tolerance

Quality Measuring Capabilities

As part of our quality commitment, we provide several CNC machining quality measuring equipment and capabilities, including:

- Multiple CMM’s with Zeiss as a standard

- Surface Tester

- Hardness Tester

- Comparator

- Romer Absolute 7520 (x2) & 7540 (x1)

- Zoller tool setter

- ISIR

- PPAP

- FAI

- Non-destructive testing

- Optical Measuring

- Digital Profilometer and Comparator

- Portable 3D Measuring Arm

- Coordinate Measuring Machine

Flexible Machining

Anchor Harvey’s linear flexible machining systems provides our team with the ability to run repeat orders with no setup – making on-demand production a reality for our customers. Once a part is set up in our flexible systems it remains resident, allowing us to machine small quantities as efficiently as large runs.

Customers can create as many pieces as they need more efficiently – from prototype to high volume:

- Prototyping — 1 to 10 pieces

- Low volume to medium production — 10 to 100 pieces

- High volume capability production — 100 to 50,000 pieces

Thermal Deburring

Our thermal deburring process underscores our commitment to quality, error-free components. Compared to manual deburring, thermal applications achieve a higher-quality deburr with the ability to repeat that success every time at scale.

In short: our customers can trust that our thermal deburring process delivers more efficient, repeatable, and reliable results.

Real-Time Machine Monitoring

Anchor Harvey’s machine monitoring software gives real-time information to help maximize the efficiency of our equipment. This software combines our tool life monitoring, NC program storage, job scheduling, machine status, and more—all into one system.

Customized Stocking Programs

As part of our global supply chain management, we offer a stocking program where our customer-centric team can carry your finished inventory at no cost – whether the component was machined domestically or through one of our international partners.

Further, customers have access to consignment, Kanban, Min/Max stocking available with expanded warehousing services.

Custom MRP Programming

Our in-house software engineering department continually develops our custom Manufacturing Resource Planning system, which tracks all aspects of our jobs from quotation to shipment.

This gives us the ability to custom tailor our software as our company and customer needs change, including customer-specific modules such as real-time part status updates, advanced shipping notification, and more.

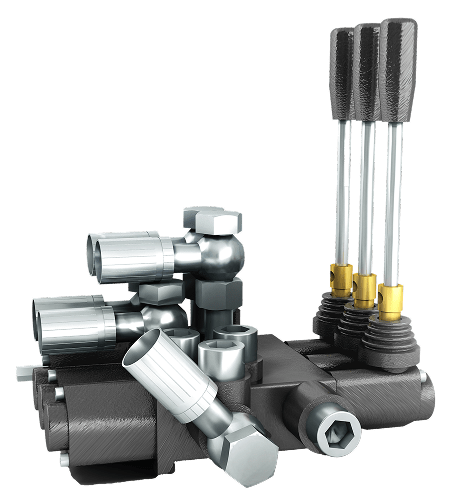

Value Added & Pre-Assembly Options

Anchor Harvey provides value-added assembly and several ultrasonic washing solutions for our customer’s products to enhance the assembly process, including:

- Expander plug insertion

- Bearings and Bushings

- Heli coil insertion

- Parts bag kitting

- SAE plug insertion

- Internal saw cutting and milling

- Welding

Featured Capabilities

Featured Capabilities

CAREERS