Our Commitment to CNC Machining Quality

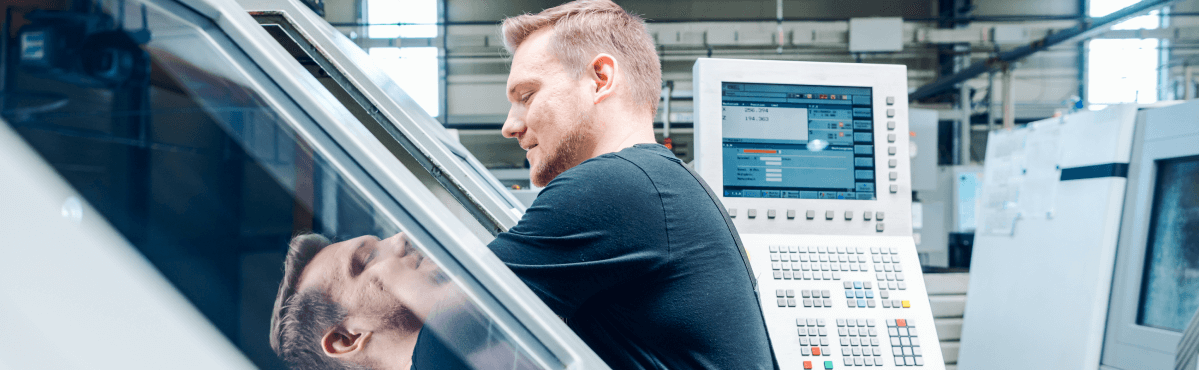

Anchor Harvey is dedicated to providing the highest quality machined products to nearly any industry. We stake our reputation on the quality of both our own production methods and those of our partnered facilities.

Each of our customer relationships is cultivated through a history of quality work and strict production standards. We invest in the latest equipment to ensure adherence to the highest quality standards.

With an integrated CNC machining process that boasts an industry-leading rate, customers can have confidence in our quality- and data-driven approach.

Precision is Our Promise

With an unwavering commitment to quality, our systems and processes have been developed to deliver any machined solution for our customers.

Beginning with consistent suppliers and trusted sources that know the needs of our customers, we apply the latest technology and processes to meet the highest quality standards of any project.

Our team leverages the following tools and strategies to ensure every project meets the highest standards of accuracy and reliability for our customers:

- Real-time Data Acquisition and Monitoring: We leverage industry-leading software that looks at tool life, NC program storage, job scheduling, and machine operations to monitor the process in real-time.

- Preventative and Predictive Maintenance: We leverage data to predict potential issues before they occur and to make decisions that enhance production efficiency. Our team also identifies trends that may lead to equipment failure and address them before problems arise – reducing downtime and maintaining operational efficiency.

- Certifications and Compliance: We hold CNC machining industry certifications like ISO 9001 and many others, which further underlines our commitment to quality control through industry standardized practices.

- Parts Washing: Our multistep parts washing process ensures that our CNC machining equipment and facility are clean and minimize contamination, successfully meeting 0.5mm max particle requirements.

- Six Sigma and SPC (Statistical Process Control): We apply Six Sigma and SPC methodologies to ensure consistent process control and quality improvement.

- Advanced Technology and Capital Investment: We continually invest in upgrading technology and machinery – like Zoller inspection and measurement machines – which supports our data-driven approach and enhances the overall machining process control and quality standards.

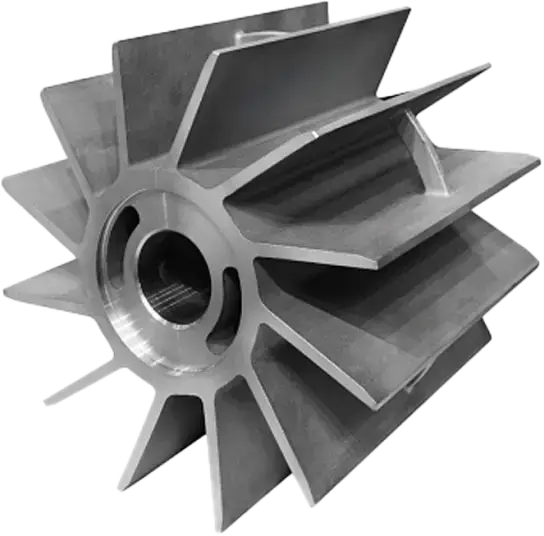

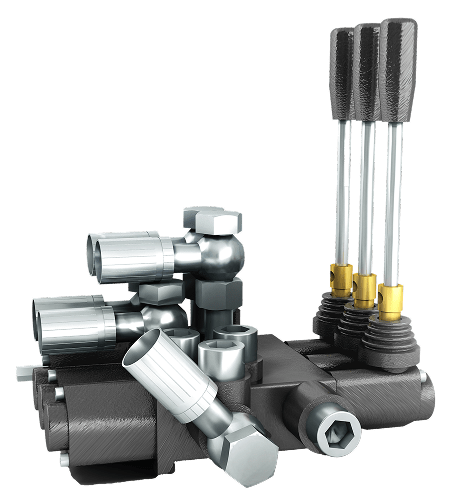

Featured Capabilities

Featured Capabilities

CAREERS