Assembly & Inspection Overview

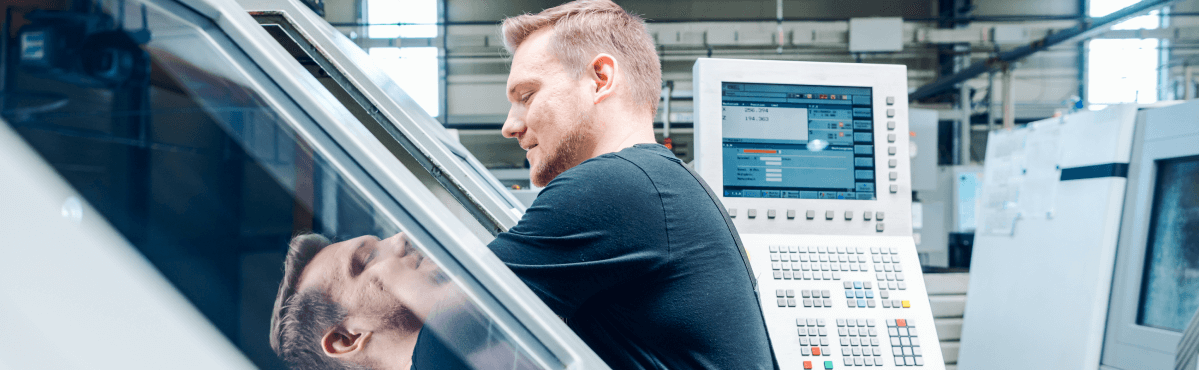

Anchor Harvey’s CNC machining process leverages our state-of-the-art forging assembly and inspection procedures to ensure our products are made to the highest standard, honed over our company’s 100 years of industry leading metal machining knowledge and experience.

We guarantee the quality of all of our machined products, and the in-house inspection methods and assembly options we provide are part of our quality guarantee.

Onsite Assembly Services

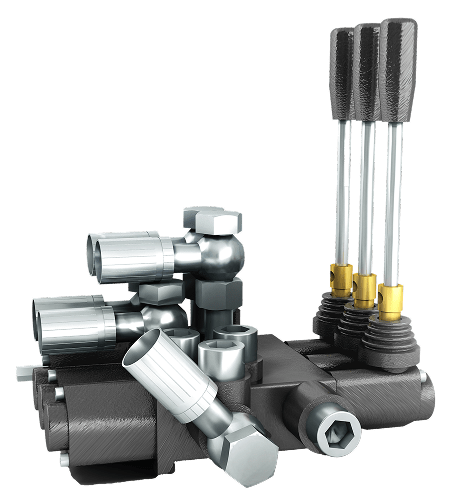

Anchor Harvey provides a complete suite of in-house assembly services across our CNC machining facilities, including , press plugs, hydraulic presses, magnetic locating stops, job kitting, bearings, bushings and more.

Our assembly inspection process always samples 100% of machined products and are verified for install by our quality department personnel. Our components are assembled in a clean, enclosed space separated from the manufacturing floor with an independent air recirculation and climate control system to ensure quality machined products – each and every time.

In-House Inspection Services

Our thorough onsite inspection capabilities include full service inspection to ensure all finished parts meet strict quality assurance standards.

As part of our best-in-class process, Anchor Harvey provides inspection per part-specific Control Plans with feedback to Process Failure Mode Effects Analysis (FMEA). We invest in the latest aging technology to ensure the highest quality standards, including CMMs, optical scanners, profilometers, bore scopes, air gauges, and Johnson gauges.

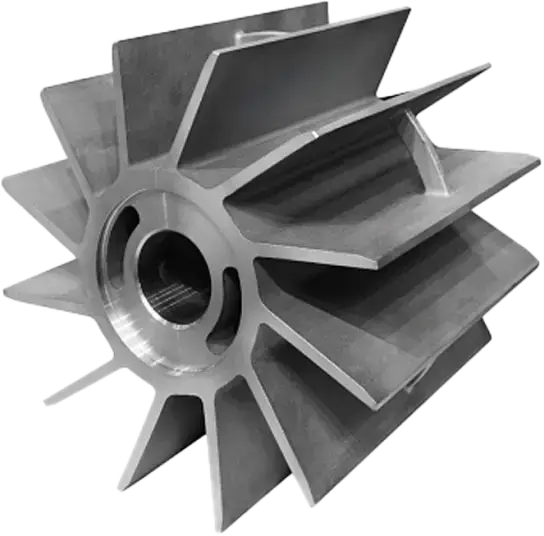

Featured Capabilities

Featured Capabilities

CAREERS