supply chain

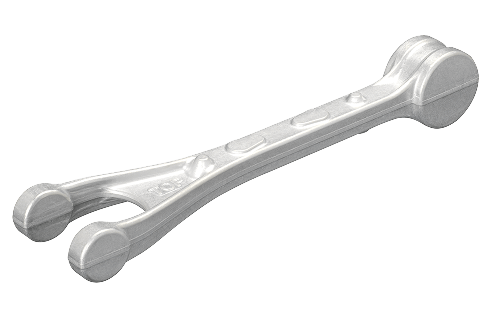

FORGING

supply chain

FORGING

supply chain

FORGING

supply chain

FORGING

supply chain

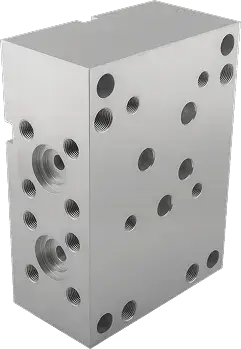

MACHINING

SUPPLY CHAIN FORGING

supply chain

MACHINING

SUPPLY CHAIN FORGING

supply chain

MACHINING

SUPPLY CHAIN FORGING

supply chain

MACHINING

SUPPLY CHAIN FORGING

Our Products

fluid passages.

No Matter the Industry,

We Flex to Solve What You Need

No Matter

the Industry,

We Are Part of

Everything You do.

INSIGHTS & EDUCATION

Average length of

customer relationship

Cellular

Forging Lines

Number of

CNC Machines

CAREERS